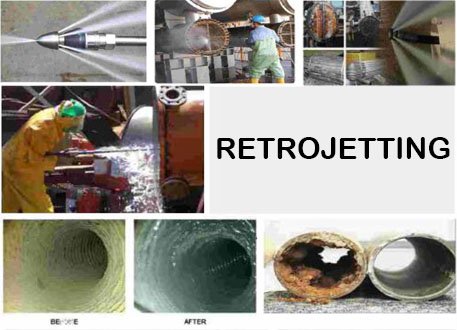

Retro jetting has been widely used in Industrial Cleaning application for the removal of deposits from process lines, tube bundles, heater coils and sewer lines. Retro jetting can be described as a cleaning system designed for internal and external cleaning of pipe. Due to the nature of the working process, retro jetting has been utilized by Oil, Gas and Industrial Companies for commissioning purposes prior to process lines being in put into service pre commissioning stage of new build oil and gas plants, Industrial pipeline process maintenance. Retro jetting offers a superior system of cleaning process pipelines than conventional flushing procedures. There are several plus factors that can be recognized by understanding the process of cleaning that retro jetting can achieve.

PT. FORTUNA RetroJetting superior cleaning factors are due to the High Pressure Nozzles with various water Jets movements into the pipe system with a High Pressure and large volume of water. The nozzle water jets are allowed to travel through the pipe or tube systems by the natural pulling force created by rearward facing water jets on the nozzle head. When these powerful water jets pass over any internal debris the debris is forced out the pipe system.

Many customers choose the method due to the time saving, the reduced water consumption, and the high level of cleanliness achieved to meet and supersede their specification. Pipeline configuration will often determine the type of nozzle selection and the pressure and flow requirements of the high pressure pump unit. Experienced operators ensure the optimum method selection for each application applying specialised tools, fit for nozzles, abrasives, and chemical solutions to ensure every project is completed.